제품소개

> 제품소개 > 신재생에너지

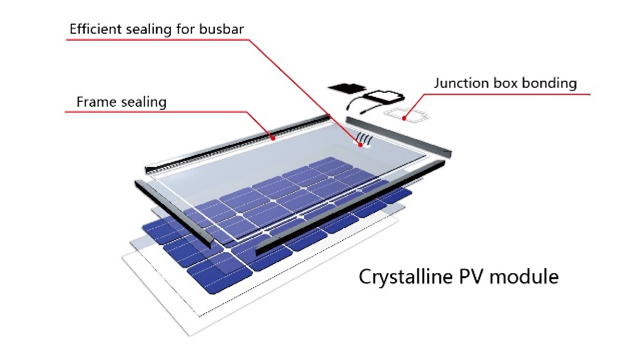

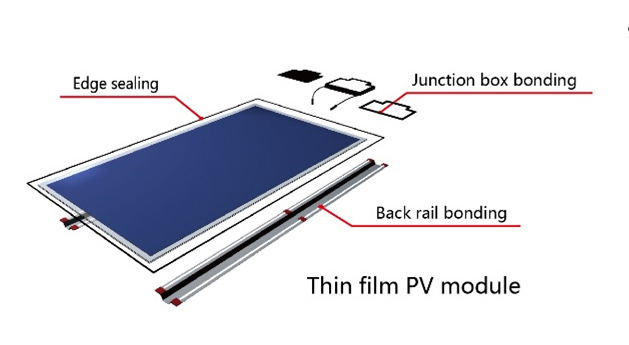

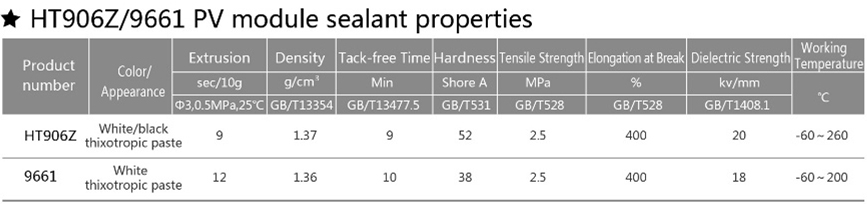

PV module sealant HT906Z/ 9661

HT906Z Junction box and module sealant

- Oxime system, white/black

- Good adhesive property to aluminum, glass, TPT/TPE backsheet, PPO/PA junction box.

- Curing fast and thixotropic paste.

Approved UL 94V-0 (refer to E248611), SGS, TUV, and ROHS authentication. - Package Specification :

310ml/cartridge 25cartridges/carton

400ml/sausage 28 sausages/carton

600ml/sausage 20 sausages/carton

20kg/drum

270kg/drum

9661 Junction box and module sealant

- Alcohol system, white.

- Good adhesive property and sealing to module frame and junction box.

- Eco-friendly, non-corrosiveness, thixotropic paste.

- Approved UL 94V-0 (refer to E248611), SGS, TUV, and ROHS authentication.

- Package Specification :

310ml/cartridge25cartridges/carton

20kg/drum

600ml/sausage 20 sausages/carton

270kg/drum

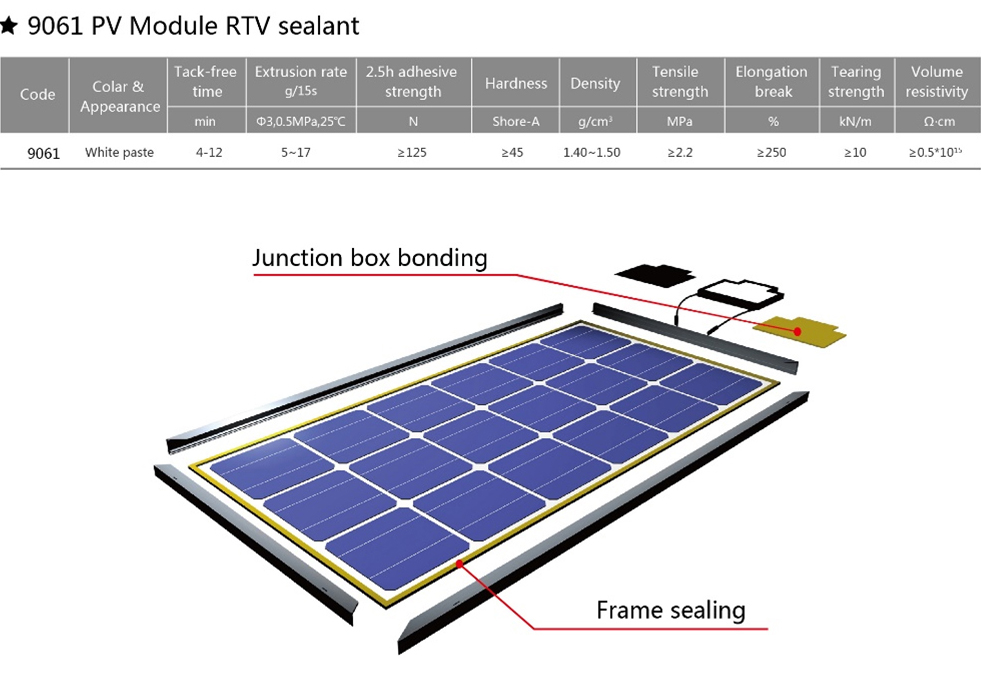

PV module RTV sealant 9061

9061 PV module RTV sealant

- One-component, RTV de-ketoxime type; Black/White

- 2) Good adhesives to Aluminum, glass, TPI/TPE, PPO

3) Great compatibility with different kinds of EVA films - 4) Good resistance to deformation

5) Pass 85°C&85%RH test, and best resistance to yellowing

6) For aluminum frame sealing and junction box bonding - 7) Used in bonding fixed between th in-film solar cell's metal

holderand glass

8) Pass UL Certification (HB) -

Package Specification :

White 9061E4 310ml/cartridgen 25cartridges/carton

White 9061E2 400m l/sa usageQ 28sausages/carton

White 9061E7270kg/drum

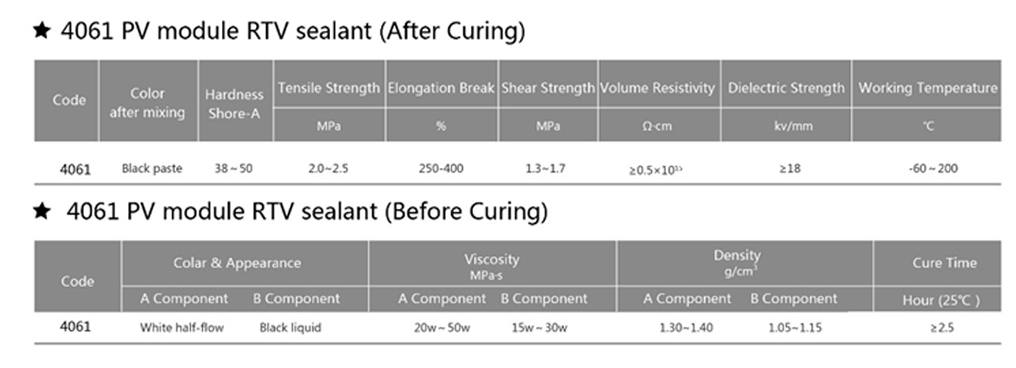

PV module RTV sealant 4061

4061 PV module RTV sealant (Two Components)

- Two-component, Condensation RTV, use for bonding

- Fast curing at room temperature

- Pass 85%RH test, and best resisllnce to yellowing

- Good adhesives to Aluminum, glass, TP7/TPE, PPO

- Good shock resistance and electrical insulation

- Foraluminum frame sealing, junction box bonding, and bus barseahng

- Used in bonding fixed between th in-film solar celfs metal holderand glass

-

Package Specification :

White A Component 4061 AS 180kg/pail

Black B Component 4061B2 18kg/pail

White A Component 4061A7 lOkg/pail

Black B Component 4061B1 Ikg/pail

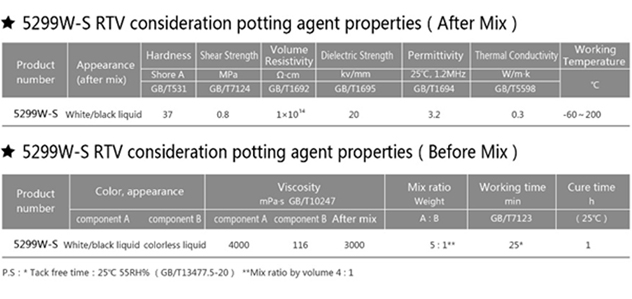

RTV Potting sealant 5299W

5299W-S potting sealant (Two Components)

- TTwo component, white/black(A component only)Q

- Static mix and the mix ration is 5:1 by weight;

- Good durability properties, moisture resistance, fast curingQ

- Excellent adhesive property with plastic .rubber. PA and PPO material;

- Approved UL 94V-0 (refer to E248611). SGS, TUV# and ROHS authentication.

-

Package Specification :

A componentn lOkg/pail

B component 2kg/csn

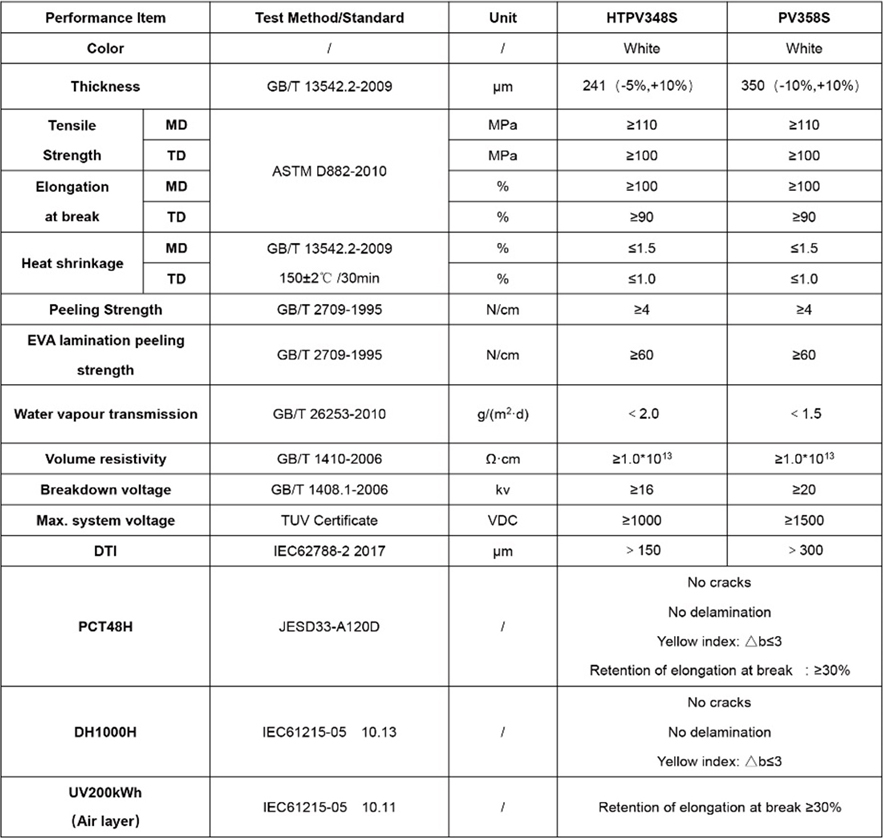

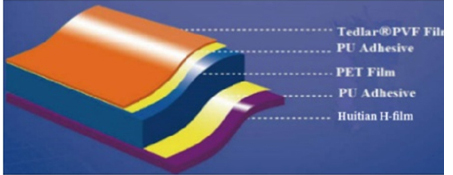

PV solar back sheet film KPH

- The 1st polyolefin film with TI value above 90 C(94.75 C) in solar industry.

- It has passed 120 KWh/sqm intensity UV under high humidity condition strict test.

- High water vaporresistance, effectively prevent snail strip happening.

- High thermal resistance, high insulation, high water proofand high adhesion.

Technical data

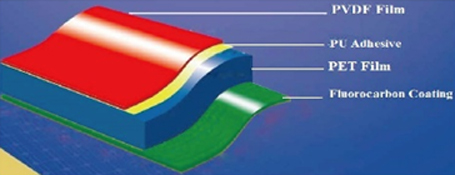

PVsolar back sheetfilm TPH

- Heatresistance : TI>94.75 ° C, the best polyolefin film for PVindustry.

- High insulation : Melting point > 160° C, which can be used in 150°C laminated conditions ,H film is not pierced. High resistivity, CTI > 600V.

- High weatherresistance. Both sides can withstand 300kwh/m2 dry UV radiation or 120 kwh/m2 UV+DH test, no yellowingor cracking.

- High adhesion : Peeling strength of BS / EVA >100N/cm,low attenuation after DH, PCT, UV + DH test.

- High water vapor barrier : The WVTR ofthe solar backsheetis less than 1.3g/(m2*day ) (tested byinfrared method), 20% to 50% less thanthe similar backsheet.

Technical data

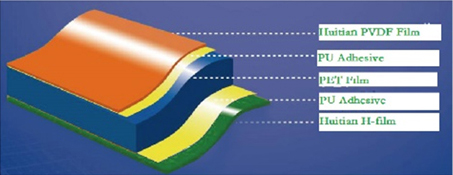

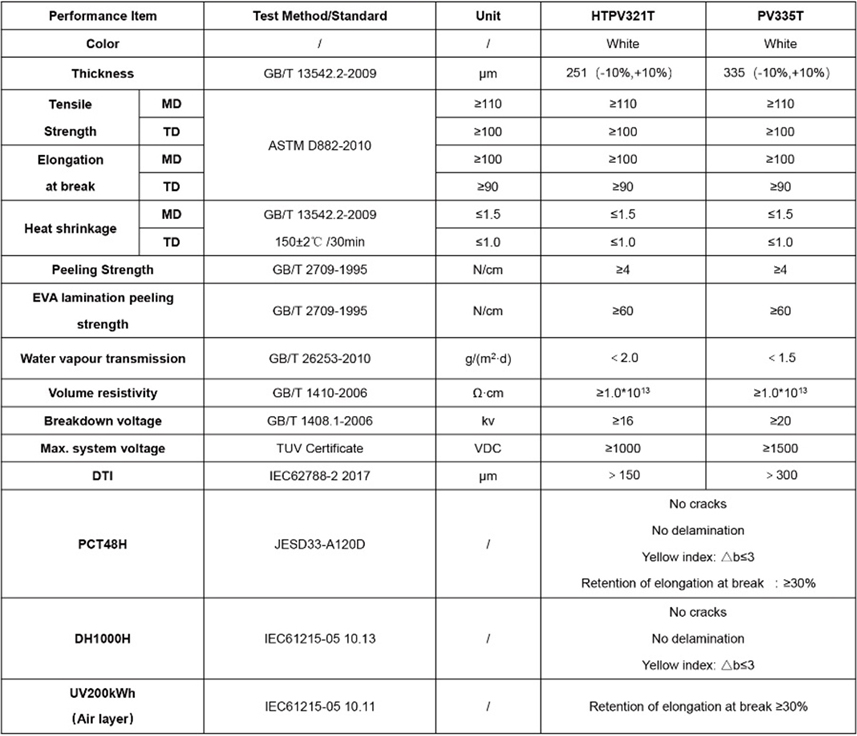

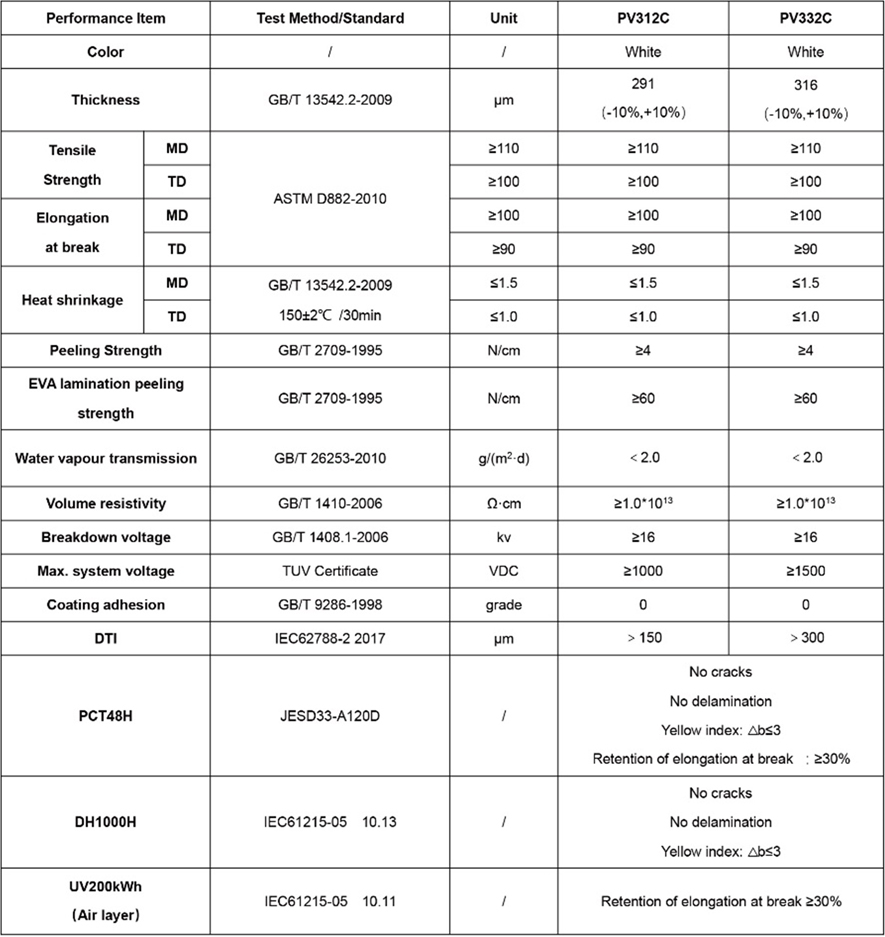

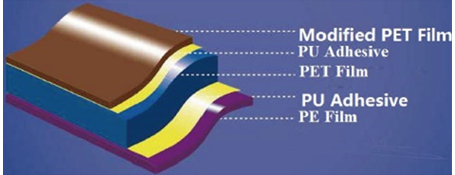

PV solar back sheet film KPC

- the outer layer is PVDF film , the inner layer is fluorocarbon coating , Double fluoride.

- High adhesive ability, high coating adhesion.

- High adhesion,has good adhesion to common encapsulation materials.

- High heat dissipation, high reflectivity.

- Excellent resistance to hot and humid.

Technical data

PV solar back sheet film PPE

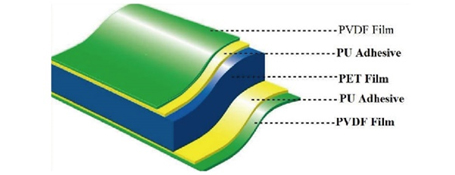

- 3 layers of functional polymeric film , the outer and inner layer are both PVDF Film, Double fluoride.

- Ultra high weatherability. high reliability.

- high adhesion,has good adhesion to common encapsulation materials.

- good water vapor resistance.

- apply to the 1500V system, effectively reduce

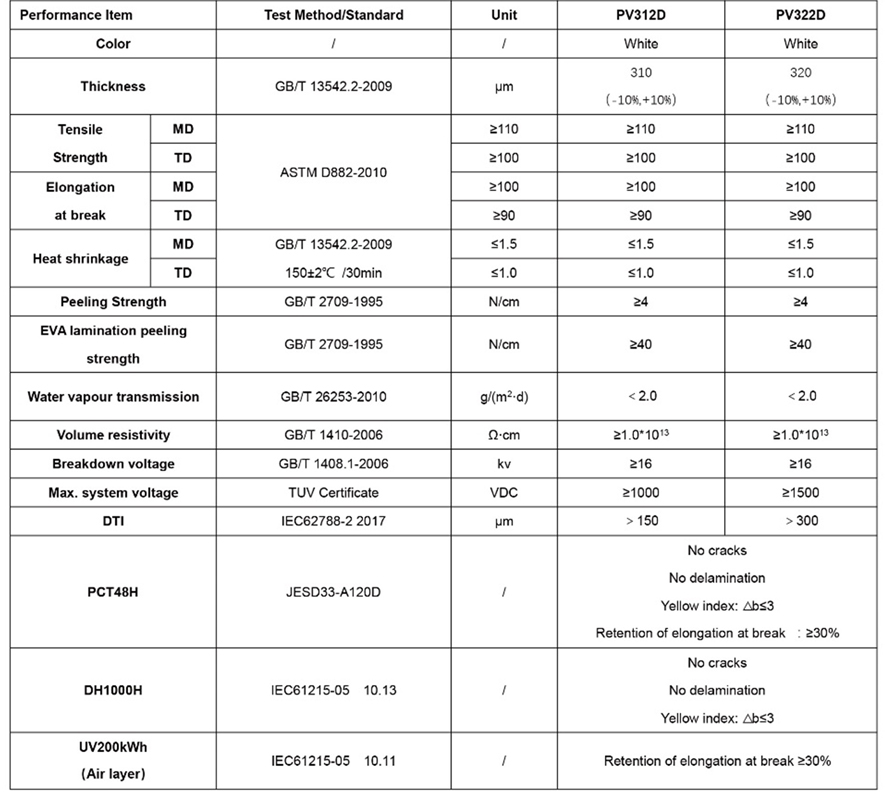

Technical data

PV solar back sheet film PPE

- the outer layer is PVDF film , the inner layer is fluorocarbon coating , Double fluoride.

- High adhesive ability, high coating adhesion.

- High adhesion,has good adhesion to common encapsulation materials.

- High heat dissipation, high reflectivity.

- Excellent resistance to hot and humid.

Technical data